Pune International Exhibition Convention Center(PIECC), MOSHI, PIMPRI CHINCHWAD, PUNE

Welcome to PRECITECH - Precision Engineering, Machine Tool Technology Show 2024

PRECITECH - PRECISION ENGINEERING, MACHINE TOOL TECHNOLOGY SHOW 2024 will take place from 07- 10 Oct 2024 at Pune International Exhibition Convention Center(Piecc), Moshi, Pimpri Chinchwad, Pune, India. PRECITECH marks a pioneer in networking events for quality Manufacturing sector in the industrial hubs. The industry seeks to leverage "PRECISION MEETS PERFORMANCE". It signifies the seamless integration of accuracy and effectiveness, leading to outstanding results and accomplishments. It's a reminder that when precision and performance align, greatness is within reach. It also focuses on technology transfer opportunities between its key stakeholders, which PRECITECH is poised to provide and enable industry professionals to engage in collaborative discussions and idea-sharing while conserving valuable resources. PRECITECH comprehensively encompasses Advanced, Intelligent, and Smart Manufacturing, as well as ancillary industries and other technologies that will shape the manufacturing landscape of the future.

The global community is turning its attention to India for precision engineering and meticulously calibrated technology, all alimed at achieving optimal results in valued production. India is already a significant contributor to the global market, supplying finely crafted components in

substantial quantities to various sectors including aero engineering, aerospace, defense, automobile, automotive, medical equipment, food processing, oil and gas, textile and infrastructure. PRECITECH will enjoy the strong backing of industry leaders and receive support from various industry associations, all working in tandem to bolster their members manufacturing capabilities as part of the Atma Nirbhar Bharat (Make in India) initiative. These ambitious endeavors will be spearheaded by seasoned professionals with more than 28 years of experience in engaging with the industry and delivering top notch exhibition services

The core mission of PRECITECH is to advance and foster the well-organized growth, development, and enhancement of the Manufacturing in the Machine Tools industry. It acts as a Networking platform for enabling technology transfer, production facilities, improved & measured manufacturing and finished components for auality products amongst the industry participants.

Exhibitor Profile

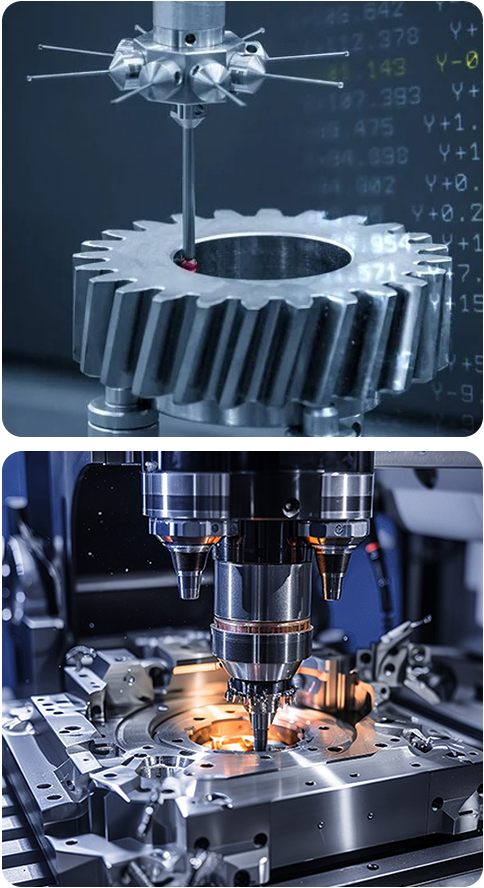

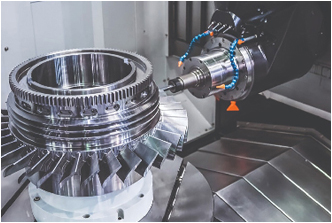

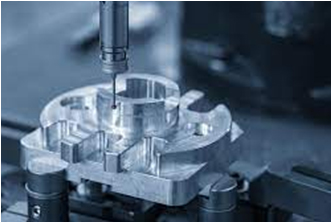

Metal Cutting

Encompasses cutting tools, drills, inserts, tips, and materials such as carbide, tungsten, titanium and diamond, as well as specialized cutting tools and associated accessories. It also includes power and pneumatic air tools, tool and work holders, and a wide range of CNC machines, including MULTI-AXIS, VMC, HMC, wire-cut, EDM, hobbing, bevelling, grinding and abrasive tools machines.

Metal Forming

Encompasses a variety of processes and equipment, including laser marking, cutting, plasma cutting, welding, bending, power press and press brake, Punching machines, deburring, machines for product cleaning and finishing, coating equipment, and machinery for forging and die-casting.

Metrology

Covers a wide array of activities related to testing, measuring, inspection, including calibration, accuracy measurement, Coordinate Measuring Machine, mechatronics – mechanics, electrical, electronics, and computing to generate a simpler, more economical and reliable system. for measuring, and quality control.

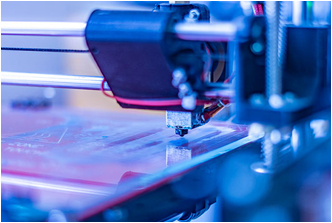

3D & Additive Manufacturers

Reverse engineering, section includes CAD/CAM software, 3D scanning and printing technology, additive manufacturing, as well as technologies for manufacturing polymers, composite materials, metals, and lightweight materials. Appropriate for Development & research, before production line.

Product Finishing

Encompasses a variety of processes, Ultra precision Grinding, Abrasive, Sand paper, Brush, Vibrating Screen, Metal treatment, Cleaning, Deburring, Drying, Polishing, Coating & Finishing.

Metal Injection Moulding, Forging and Casting

Encompasses a variety of processes and equipment, including Melting Casting, Cutting, machinery for forging and die-casting.

Automation & Robotics

Encompasses motion engineering, drive and control systems, welding and material handling, power transmission, and applications in the most mechanised manufacturing improve production controls in major Industry vertical.

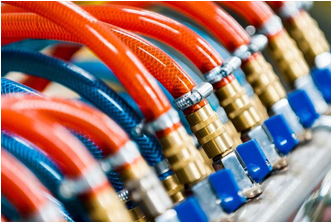

Fluid Power

Encompasses hydraulic, pneumatic systems, air compressors, and vacuum, generators. Oil and Lubrication helps in Improving Production capacities.

Plant & Asset Management

Encompasses research and development, training, logistics, and supply chain operations.Visitor Profiles