Mark you calendar for the upcoming exhibition- 3D GRAPHY ENGINEERING & MEDICAL (3D GEM) 2025, happening from 09- 10 Oct 2025 at J N Tata Auditorium, Indian Institute of Science Bengaluru, Karnataka, India. An international event with a global convergence of industries promoting 3D Printing & 3D Visualisation. It is the only event conglomerate in India where all the End users are the active supporter's of the event joining from different industries and specialisation to learn and explore the possibilities of 3D Printing & 3D Visualisation. We have Industry association members from Engineering, Industrial Manufacturing, Fashion, Jewellery, Entertainment. Lifestyle, Dental and Medical from different specialisation all join to participate in the event sharing their problem statements expecting solutions from 3D Technology. The theme of the event is “Democratising 3D Technology through education & research to benefit all”. The event is organised by 3D Graphy, Supported by Host Partner Indian Institute of Science Bengaluru and the Ministry of Electronics & Information Technology, Govt. of India, MSME Start up’s in 3D technology, Engineering equipment manufacturing companies in Industrial Manufacturing, 3D Printing Service Providers, Medical Device Companies, Manufacturing cos, Entrepreneurs looking for different business opportunities in 3d Printing and 3D Visualisation and 28 different industry associations. The event is in line with Government of India’s initiative to promote indigenous manufacturing with Atmanirbhar Bharat – Make in India with Industry 4.0.

Polymer-based parts for proof of concept and metal with carbon fibre for end-use parts.

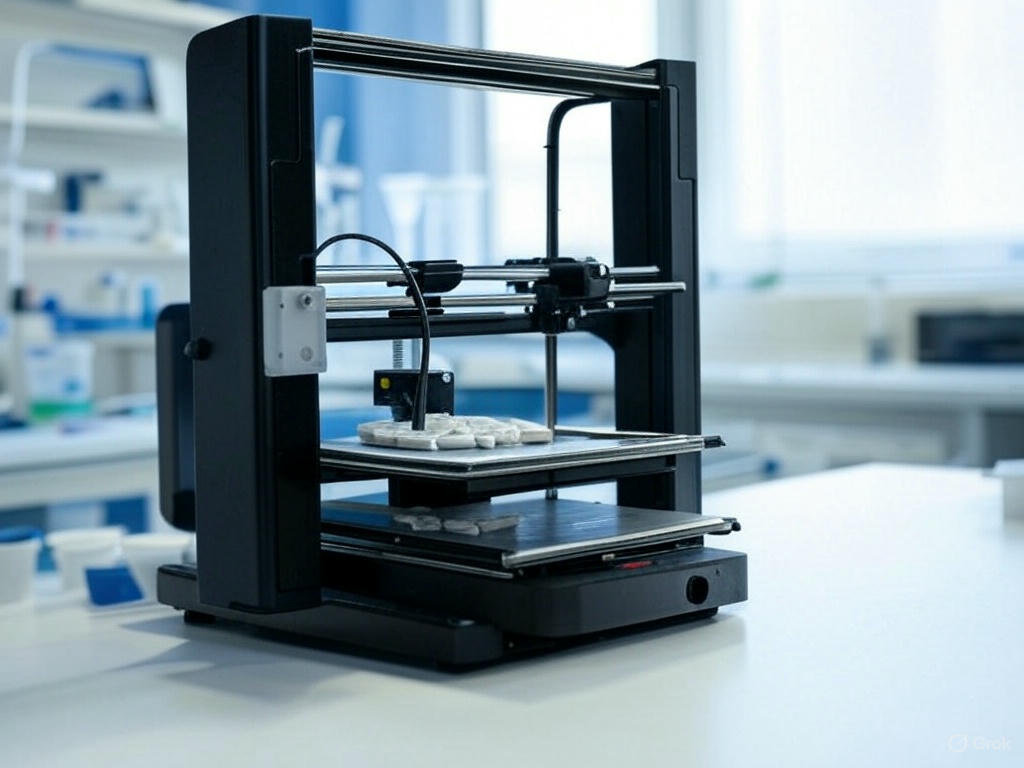

Resin-based 3D printer for prototypes and end-use parts.

Lattice structure 3D-printed metal parts.

3D printed metal parts using electron beams and lasers to form melt pool.

Polymer-based 3D printed prototype and end-use parts.

Used in construction of homes, monuments, and complex structures.

3D printed metal components using electric arcs for melt pool formation.

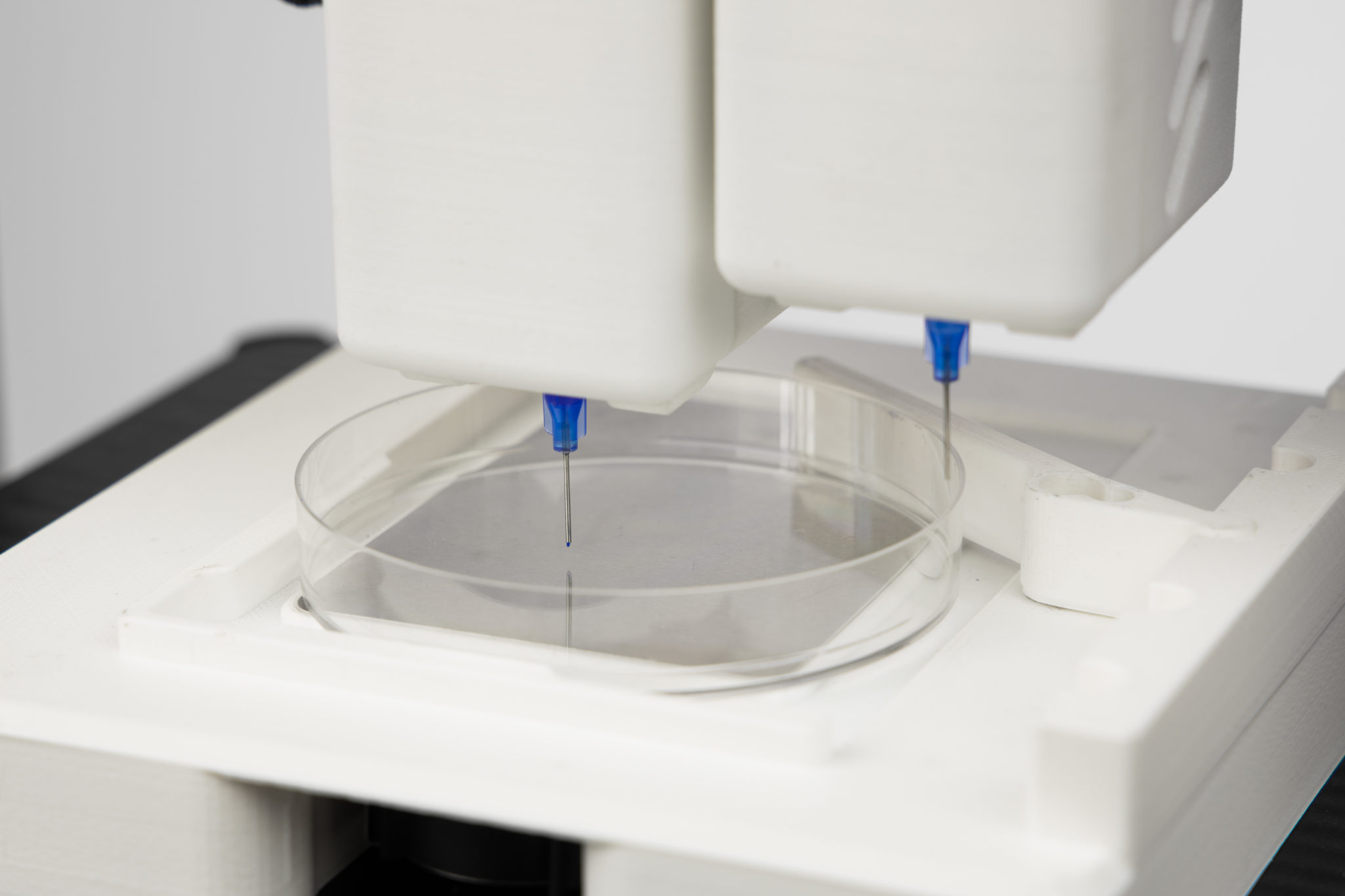

Printing of bioinks, collagens, and artificial tissues.

Simulation and modelling for design and real-world processes.

Used for reverse engineering.

Scanner for dental applications.

Includes Augmented Reality, Virtual Reality, and Mixed Reality solutions.